BLOG

Understanding Heavy Duty Industrial Casters: The Backbone of Efficient Material Handling

2025-05-31

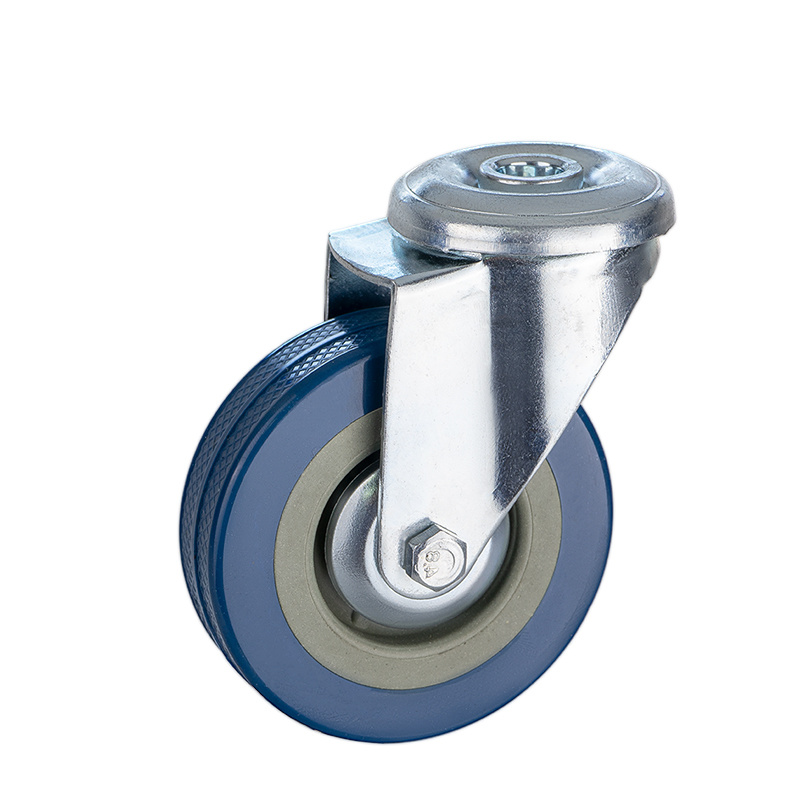

Heavy duty industrial casters are specialized wheels designed to support and facilitate the movement of heavy loads in industrial and commercial settings. They are engineered to withstand substantial weight and endure rigorous conditions, making them an indispensable component in warehouses, manufacturing plants, and retail environments.

The construction of heavy duty industrial casters typically

Heavy duty industrial casters are specialized wheels designed to support and facilitate the movement of heavy loads in industrial and commercial settings. They are engineered to withstand substantial weight and endure rigorous conditions, making them an indispensable component in warehouses, manufacturing plants, and retail environments.

The construction of heavy duty industrial casters typically involves robust materials such as steel or heavy-duty plastic and features a strong wheel design. The wheels often come with ball bearings to ensure smooth rotation and ease of movement, which is crucial when transporting heavy equipment or goods. Additionally, these casters may be equipped with brakes to secure loads in place, enhancing safety during operation.

One of the primary advantages of using heavy duty industrial casters is their ability to improve efficiency in material handling. By allowing items to be moved effortlessly across various surfaces, these casters reduce the physical strain on workers and decrease the time required for transporting goods. This efficiency is especially beneficial in environments where frequent movement of heavy items is necessary.

Moreover, heavy duty casters are available in various designs to cater to specific needs. For instance, swivel casters offer greater maneuverability, enabling easy navigation in tight spaces, while rigid casters provide stability for straight-line movement. Choosing the right type of caster can significantly impact overall productivity and workflow.

The application of heavy duty industrial casters extends across numerous industries. In manufacturing, they are commonly used on assembly lines for transporting materials and finished products. In warehouses, they facilitate the movement of pallets and storage racks, optimizing space and accessibility. Retail establishments utilize these casters on display units and carts, enhancing customer experience by providing easy access to products.

When selecting heavy duty industrial casters, it is essential to consider factors such as load capacity, wheel diameter, and the type of surface they will be used on. Ensuring that the casters are compatible with the intended application will lead to better performance and longevity. Regular maintenance, such as inspecting for wear and tear, is also vital to keep the casters functioning optimally and to extend their lifespan.

In conclusion, heavy duty industrial casters are an integral part of effective material handling in various settings. Their durability, efficiency, and versatility make them a key asset for businesses aiming to streamline operations and improve workplace safety. By understanding their features and applications, you can make informed decisions when incorporating these casters into your operations.

The construction of heavy duty industrial casters typically involves robust materials such as steel or heavy-duty plastic and features a strong wheel design. The wheels often come with ball bearings to ensure smooth rotation and ease of movement, which is crucial when transporting heavy equipment or goods. Additionally, these casters may be equipped with brakes to secure loads in place, enhancing safety during operation.

One of the primary advantages of using heavy duty industrial casters is their ability to improve efficiency in material handling. By allowing items to be moved effortlessly across various surfaces, these casters reduce the physical strain on workers and decrease the time required for transporting goods. This efficiency is especially beneficial in environments where frequent movement of heavy items is necessary.

Moreover, heavy duty casters are available in various designs to cater to specific needs. For instance, swivel casters offer greater maneuverability, enabling easy navigation in tight spaces, while rigid casters provide stability for straight-line movement. Choosing the right type of caster can significantly impact overall productivity and workflow.

The application of heavy duty industrial casters extends across numerous industries. In manufacturing, they are commonly used on assembly lines for transporting materials and finished products. In warehouses, they facilitate the movement of pallets and storage racks, optimizing space and accessibility. Retail establishments utilize these casters on display units and carts, enhancing customer experience by providing easy access to products.

When selecting heavy duty industrial casters, it is essential to consider factors such as load capacity, wheel diameter, and the type of surface they will be used on. Ensuring that the casters are compatible with the intended application will lead to better performance and longevity. Regular maintenance, such as inspecting for wear and tear, is also vital to keep the casters functioning optimally and to extend their lifespan.

In conclusion, heavy duty industrial casters are an integral part of effective material handling in various settings. Their durability, efficiency, and versatility make them a key asset for businesses aiming to streamline operations and improve workplace safety. By understanding their features and applications, you can make informed decisions when incorporating these casters into your operations.

Key words:

RELATED NEWS

Comparing Different Types of Medium Duty Casters for Your Needs

2025-07-19

Introduction to Medium Duty Casters

In the realm of industrial and commercial applications, the importance of **medium duty casters** cannot be overstated. They play a crucial role in facilitating smooth movement and enhancing operational efficiency. From warehouses to workshops, these casters are engineered to handle specific weight capacities and a variety of conditions. In this guide, we will d

The Versatile Grey Caster: A Key Component in Mobility Solutions

2025-07-12

Grey casters are an integral part of numerous applications where mobility and load-bearing capacity are essential. These casters are characterized by their distinctive grey wheels, typically made from materials like rubber or polyurethane. This specific color not only enhances aesthetic appeal but also offers practical benefits like minimizing floor scratches and noise reduction during operation.

Innovative Design of Diamond Casters: Trends to Watch in 2024

2025-07-05

Innovative Design of Diamond Casters: Trends to Watch in 2024

Table of Contents

1. Introduction to Diamond Casters

2. The Evolution of Diamond Casters

3. Key Trends in Diamond Caster Design for 2024

3.1 Sustainability and Eco-Friendly Materials

3.2 Integration of Smart Technology

3.3 Ergonomic Innovations

3.4 Enhanced Aesthetic