BLOG

Understanding Heavy Duty Industrial Casters: The Backbone of Efficient Mobility

2025-08-09

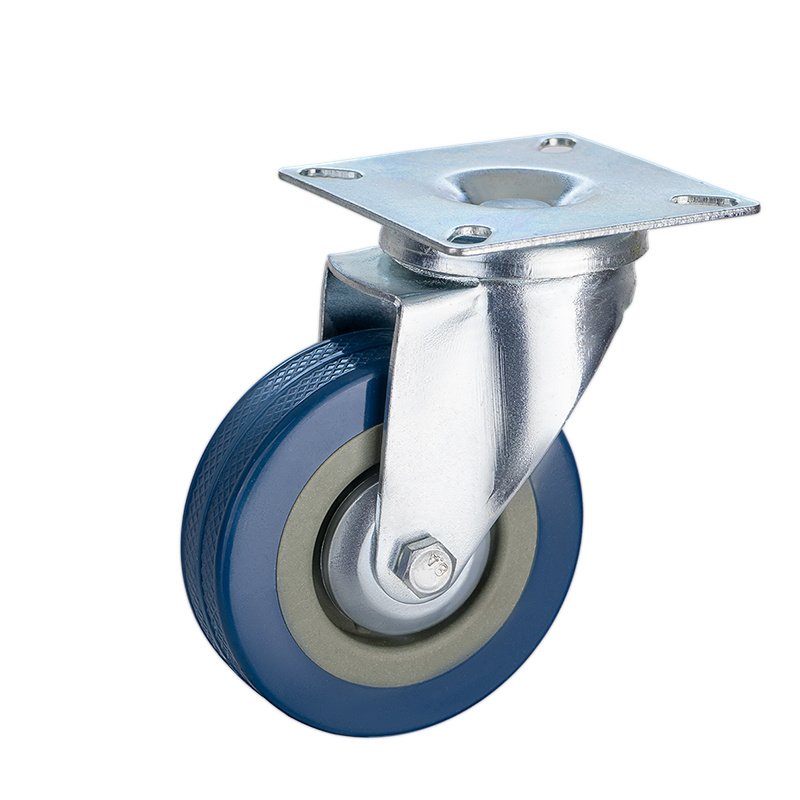

Heavy duty industrial casters are crucial components in various industrial applications, providing the necessary support and mobility for heavy equipment and machinery. Designed to withstand significant weights and rigorous conditions, these casters ensure that your operations run smoothly, improving overall efficiency.

One of the primary features of heavy duty industrial casters is their construc

Heavy duty industrial casters are crucial components in various industrial applications, providing the necessary support and mobility for heavy equipment and machinery. Designed to withstand significant weights and rigorous conditions, these casters ensure that your operations run smoothly, improving overall efficiency.

One of the primary features of heavy duty industrial casters is their construction. Typically made from robust materials like steel or reinforced plastic, they are engineered to endure heavy loads. The wheel diameter also plays a vital role; larger wheels can distribute weight more evenly and reduce the risk of damage to floors. This feature not only extends the lifespan of your caster but also minimizes maintenance costs associated with flooring repairs.

Another critical aspect to consider is the wheel type. Heavy duty casters come with various wheel materials, each suited for different surfaces and conditions. For instance, rubber wheels are excellent for reducing noise and floor markings, while polyurethane wheels offer superior durability and resistance to chemicals and oils. It's essential to choose the right wheel type based on your specific application to ensure optimal performance.

Load capacity is perhaps the most significant factor when selecting heavy duty industrial casters. These casters are designed to support various weight ranges, and understanding the load requirements of your application is essential. Overloading a caster can lead to premature failure and safety hazards. Therefore, always ensure that the casters you choose meet or exceed your operational needs.

Additionally, heavy duty casters often feature advanced rolling mechanisms, such as precision ball bearings or swivel designs, which provide ease of movement and control. A well-designed swivel caster allows for quick navigation around corners and tight spaces, enhancing productivity within your workspace. When evaluating casters, consider features like locking mechanisms that provide stability when the load is stationary, ensuring safety in busy industrial environments.

Finally, regular maintenance is key to maximizing the lifespan and performance of heavy duty industrial casters. Simple practices, such as routine inspections, cleaning, and lubrication, can prevent wear and tear, ensuring that your equipment operates efficiently and safely.

In summary, selecting the right heavy duty industrial casters is essential for maintaining efficient operations in any industrial setting. By considering factors such as material, load capacity, and maintenance, you can make informed decisions that enhance mobility and productivity in your workplace.

One of the primary features of heavy duty industrial casters is their construction. Typically made from robust materials like steel or reinforced plastic, they are engineered to endure heavy loads. The wheel diameter also plays a vital role; larger wheels can distribute weight more evenly and reduce the risk of damage to floors. This feature not only extends the lifespan of your caster but also minimizes maintenance costs associated with flooring repairs.

Another critical aspect to consider is the wheel type. Heavy duty casters come with various wheel materials, each suited for different surfaces and conditions. For instance, rubber wheels are excellent for reducing noise and floor markings, while polyurethane wheels offer superior durability and resistance to chemicals and oils. It's essential to choose the right wheel type based on your specific application to ensure optimal performance.

Load capacity is perhaps the most significant factor when selecting heavy duty industrial casters. These casters are designed to support various weight ranges, and understanding the load requirements of your application is essential. Overloading a caster can lead to premature failure and safety hazards. Therefore, always ensure that the casters you choose meet or exceed your operational needs.

Additionally, heavy duty casters often feature advanced rolling mechanisms, such as precision ball bearings or swivel designs, which provide ease of movement and control. A well-designed swivel caster allows for quick navigation around corners and tight spaces, enhancing productivity within your workspace. When evaluating casters, consider features like locking mechanisms that provide stability when the load is stationary, ensuring safety in busy industrial environments.

Finally, regular maintenance is key to maximizing the lifespan and performance of heavy duty industrial casters. Simple practices, such as routine inspections, cleaning, and lubrication, can prevent wear and tear, ensuring that your equipment operates efficiently and safely.

In summary, selecting the right heavy duty industrial casters is essential for maintaining efficient operations in any industrial setting. By considering factors such as material, load capacity, and maintenance, you can make informed decisions that enhance mobility and productivity in your workplace.

Key words:

RELATED NEWS

Understanding Grey Casters: A Comprehensive Guide to Their Benefits and Applications

2025-09-20

When it comes to enhancing mobility in various applications, grey casters have gained significant popularity due to their unique characteristics and benefits. Grey casters are designed with a rubber material that is typically softer and quieter compared to traditional hard plastic or metal wheels. This makes them ideal for environments where noise reduction and floor protection are essential.

One

Safety First: The Importance of Using Diamond Casters in Workspaces

2025-09-13

Safety First: The Importance of Using Diamond Casters in Workspaces

Table of Contents

Introduction to Diamond Casters

What Are Diamond Casters?

Benefits of Using Diamond Casters in Workspaces

Enhanced Safety Features

Improved Mobility and Flexibility

Durability and Reliability

Applications of Diamond Casters in Various Industri

Understanding Market Trolley Casters: A Guide for Professionals

2025-09-06

When it comes to enhancing mobility in various applications, market trolley casters play a pivotal role. These casters are designed to facilitate the smooth movement of trolleys, carts, and other equipment in retail, logistics, and industrial settings. Understanding the fundamentals of market trolley casters is essential for professionals in the hardware tools and components industry, particularly