BLOG

Low Profile Heavy Duty Casters: The Secret to Smooth Transport in Warehouses

2025-08-16

Low Profile Heavy Duty Casters: The Secret to Smooth Transport in Warehouses

Table of Contents

1. Understanding Low Profile Heavy Duty Casters

2. Benefits of Using Low Profile Heavy Duty Casters in Warehouses

2.1 Enhanced Stability for Heavy Loads

2.2 Improved Maneuverability in Tight Spaces

2.3 Increased Efficiency and Productivity

3. Types of Low Profile Heavy Duty Casters

3.1 Swivel Casters

3.2

Low Profile Heavy Duty Casters: The Secret to Smooth Transport in Warehouses

Table of Contents

1. Understanding Low Profile Heavy Duty Casters

2. Benefits of Using Low Profile Heavy Duty Casters in Warehouses

2.1 Enhanced Stability for Heavy Loads

2.2 Improved Maneuverability in Tight Spaces

2.3 Increased Efficiency and Productivity

3. Types of Low Profile Heavy Duty Casters

3.1 Swivel Casters

3.2 Rigid Casters

3.3 Pneumatic Casters

4. Key Features to Look for in Low Profile Heavy Duty Casters

4.1 Load Capacity

4.2 Wheel Material

4.3 Brake Mechanism

5. How to Choose the Right Low Profile Heavy Duty Casters for Your Warehouse

6. Installation and Maintenance Tips for Longevity

7. Frequently Asked Questions (FAQs)

8. Conclusion

1. Understanding Low Profile Heavy Duty Casters

Low profile heavy duty casters are specialized wheels designed to facilitate the movement of heavy items in warehouse settings. Their unique low profile design enables them to handle greater weight while maintaining stability and ease of use. These casters are engineered to be durable, often featuring reinforced materials that can withstand the rigors of daily use. The low height of these casters allows for a lower center of gravity, which significantly enhances balance and reduces the risk of tipping over during transport.

2. Benefits of Using Low Profile Heavy Duty Casters in Warehouses

Implementing low profile heavy duty casters in your warehouse comes with multifaceted advantages that can streamline operations and improve efficiency.

2.1 Enhanced Stability for Heavy Loads

One of the primary benefits of low profile heavy duty casters is their exceptional stability. When transporting heavy loads, the design of these casters helps to distribute the weight evenly, thereby minimizing the risk of accidents. This stability is crucial in bustling warehouse environments where safety is a top priority.

2.2 Improved Maneuverability in Tight Spaces

With their compact design, low profile heavy duty casters enhance maneuverability in tight aisles and around corners. This feature is particularly beneficial in warehouses where space is often limited, allowing workers to navigate quickly and efficiently without causing damage to the surrounding environment.

2.3 Increased Efficiency and Productivity

Using low profile heavy duty casters can significantly boost productivity. Their ease of movement means that employees can transport goods more rapidly, reducing the time spent on manual handling. This efficiency translates to increased throughput, allowing warehouses to operate at peak capacity.

3. Types of Low Profile Heavy Duty Casters

Various types of low profile heavy duty casters are available, each designed for specific applications. Understanding these types can help in selecting the best option for your warehouse needs.

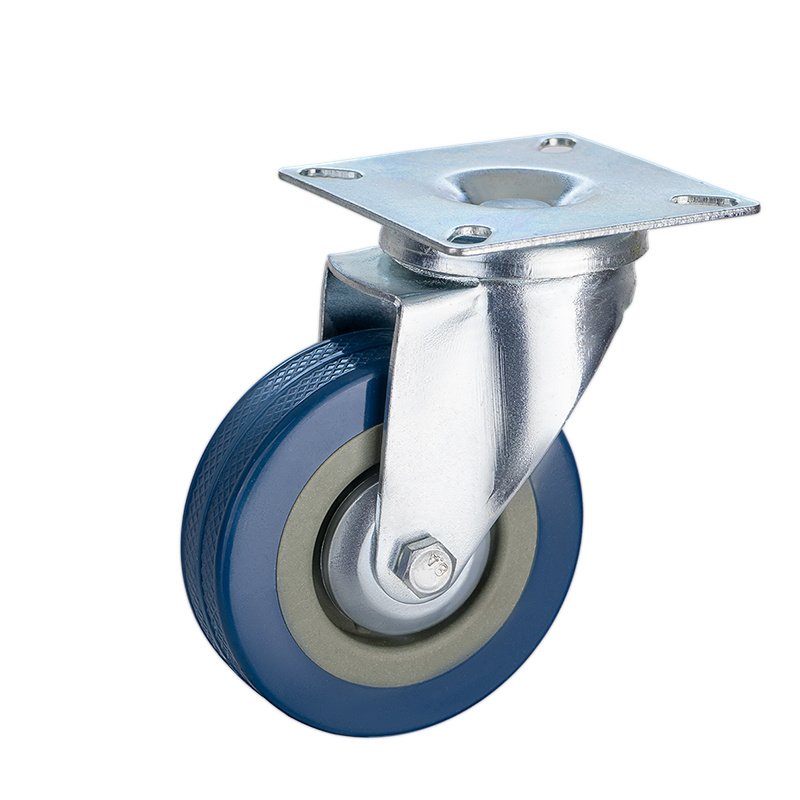

3.1 Swivel Casters

Swivel casters provide flexibility and agility, allowing for easy directional changes. They are perfect for situations where items need to be moved around corners or in tight spaces.

3.2 Rigid Casters

Rigid casters are fixed in one direction, offering stability and support for straight-line movement. They are ideal for transporting heavy loads over longer distances where maneuverability is less of a concern.

3.3 Pneumatic Casters

Pneumatic casters feature air-filled tires that provide cushioning, making them suitable for uneven surfaces. They absorb shocks and vibrations, ensuring that the transported goods remain undamaged, even on rough terrain.

4. Key Features to Look for in Low Profile Heavy Duty Casters

When selecting low profile heavy duty casters, certain key features must be considered to ensure optimal performance and safety.

4.1 Load Capacity

Understanding the load capacity of casters is critical. They must be capable of handling the specific weight of the items they will support. Overloading casters can lead to premature wear or failure, compromising safety and efficiency.

4.2 Wheel Material

The material of the wheel plays a significant role in its performance. Common materials include rubber, polyurethane, and nylon. Each has its own advantages, such as noise reduction, durability, and traction, so it’s essential to choose based on the specific warehouse environment.

4.3 Brake Mechanism

Investing in casters with a reliable brake mechanism is essential for safety, especially when dealing with heavy loads. A robust brake system will ensure that items remain stationary when not in motion, preventing accidents and injuries.

5. How to Choose the Right Low Profile Heavy Duty Casters for Your Warehouse

Selecting the right low profile heavy duty casters involves assessing various factors, including the nature of the goods being transported, the layout of the warehouse, and the frequency of use.

1. **Assess Load Requirements**: Determine the maximum weight that the casters will need to support.

2. **Evaluate the Surface**: Consider whether the warehouse floor is smooth, uneven, or has specific hazards. This will influence the choice of wheel material.

3. **Consider Frequency of Use**: For high-frequency applications, durability and ease of movement should be prioritized.

By taking these factors into account, you can ensure that the casters selected will meet your operational demands efficiently.

6. Installation and Maintenance Tips for Longevity

Proper installation and maintenance of low profile heavy duty casters are paramount to extend their lifespan and maintain optimal functionality.

- **Installation**: Ensure that the casters are mounted securely to prevent any wobbling or instability. Follow the manufacturer’s guidelines for torquing screws and bolts.

- **Regular Inspection**: Conduct regular inspections to check for wear, damage, and the condition of the wheel material. Look for cracks or warping that can affect performance.

- **Lubrication**: Apply appropriate lubricants to moving parts to reduce friction and wear. This helps maintain smooth operation and prolongs the life of the casters.

By adhering to these best practices, you can maximize the effectiveness and lifespan of your low profile heavy duty casters.

7. Frequently Asked Questions (FAQs)

What weight can low profile heavy duty casters support?

Low profile heavy duty casters can support various weights, often ranging from 500 to over 2000 pounds, depending on the specific model and configuration.

Are low profile heavy duty casters suitable for outdoor use?

Some low profile heavy duty casters are designed for outdoor use, especially those with durable, weather-resistant materials. Always check the manufacturer's specifications.

Can I replace the wheels on my existing casters?

Yes, many casters come with detachable wheels that can be replaced if they become worn or damaged. Ensure compatibility with your existing caster frames.

How do I determine the right size caster for my needs?

Choosing the right size involves considering the load capacity, wheel diameter, and the types of surfaces the casters will navigate. A larger wheel typically rolls easier and can handle uneven surfaces better.

What is the difference between swivel and rigid casters?

Swivel casters can rotate 360 degrees, offering greater maneuverability, while rigid casters are fixed and provide straight-line movement, making them ideal for stability over longer distances.

8. Conclusion

In the ever-evolving world of warehouse logistics, low profile heavy duty casters emerge as an indispensable tool for enhancing operational efficiency. Their ability to support heavy loads while providing stability and maneuverability makes them a smart investment for any warehouse. By understanding the various types, key features, and benefits, as well as following proper maintenance practices, businesses can ensure smooth transport and improved productivity. Investing in quality low profile heavy duty casters is not just a choice; it’s a strategic decision that leads to operational excellence.

Key words:

RELATED NEWS

How to Properly Install Medium Duty Casters for Maximum Performance

2025-09-27

How to Properly Install Medium Duty Casters for Maximum Performance

Table of Contents

1. Understanding Medium Duty Casters

2. Benefits of Using Medium Duty Casters

3. Choosing the Right Medium Duty Casters for Your Needs

4. Essential Tools and Materials for Installation

5. Step-by-Step Guide to Installing Medium Duty Casters

5.1 Preparing the Surface

5.2 Marking the Installation Po

Understanding Grey Casters: A Comprehensive Guide to Their Benefits and Applications

2025-09-20

When it comes to enhancing mobility in various applications, grey casters have gained significant popularity due to their unique characteristics and benefits. Grey casters are designed with a rubber material that is typically softer and quieter compared to traditional hard plastic or metal wheels. This makes them ideal for environments where noise reduction and floor protection are essential.

One

Safety First: The Importance of Using Diamond Casters in Workspaces

2025-09-13

Safety First: The Importance of Using Diamond Casters in Workspaces

Table of Contents

Introduction to Diamond Casters

What Are Diamond Casters?

Benefits of Using Diamond Casters in Workspaces

Enhanced Safety Features

Improved Mobility and Flexibility

Durability and Reliability

Applications of Diamond Casters in Various Industri