BLOG

How to Properly Install Medium Duty Casters for Maximum Performance

2025-09-27

How to Properly Install Medium Duty Casters for Maximum Performance

Table of Contents

1. Understanding Medium Duty Casters

2. Benefits of Using Medium Duty Casters

3. Choosing the Right Medium Duty Casters for Your Needs

4. Essential Tools and Materials for Installation

5. Step-by-Step Guide to Installing Medium Duty Casters

5.1 Preparing the Surface

5.2 Marking the Installation Po

How to Properly Install Medium Duty Casters for Maximum Performance

Table of Contents

1. Understanding Medium Duty Casters

2. Benefits of Using Medium Duty Casters

3. Choosing the Right Medium Duty Casters for Your Needs

4. Essential Tools and Materials for Installation

5. Step-by-Step Guide to Installing Medium Duty Casters

5.1 Preparing the Surface

5.2 Marking the Installation Points

5.3 Attaching the Casters

5.4 Testing the Installation

6. Maintenance Tips for Long-Lasting Performance

7. Common Mistakes to Avoid When Installing Casters

8. Frequently Asked Questions (FAQs)

9. Conclusion

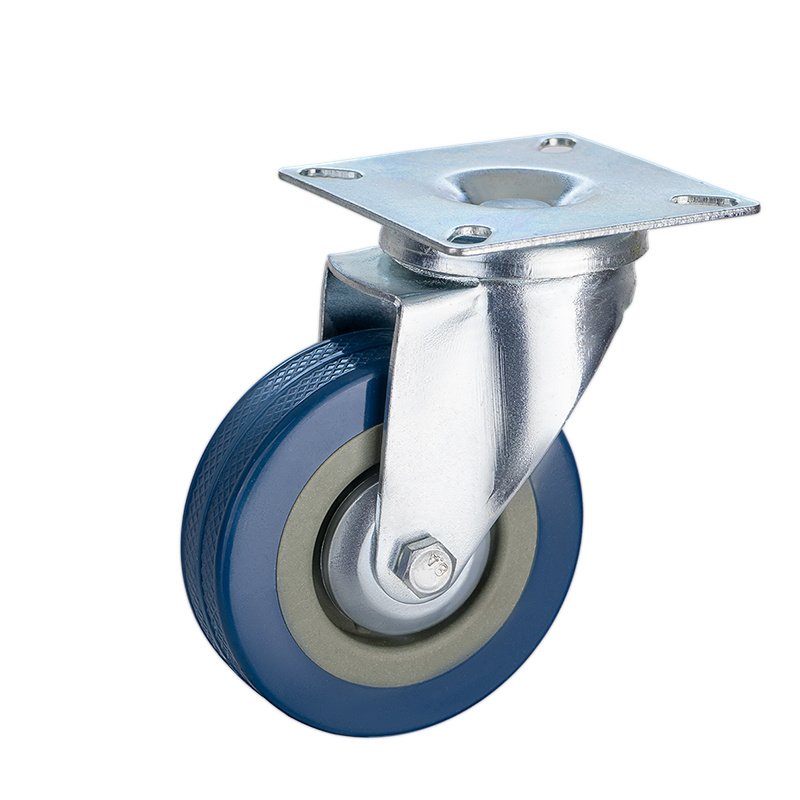

1. Understanding Medium Duty Casters

Medium duty casters are essential components for various applications, providing mobility and ease of movement to equipment and furniture. Typically rated to support loads ranging from 300 to 1,200 pounds, these casters are ideal for warehouse trolleys, tool carts, and office furniture. Their construction generally includes robust materials such as steel, plastic, or rubber, ensuring durability under typical load conditions.

2. Benefits of Using Medium Duty Casters

Utilizing medium duty casters offers several advantages, including:

- **Increased Mobility**: Casters enable smooth movement of heavy items, reducing the risk of injury while transporting them.

- **Versatility**: They are suitable for a range of applications, from industrial to residential settings.

- **Ease of Use**: Most medium duty casters feature swivel capabilities, allowing for easy navigation around corners and tight spaces.

- **Customization**: With various wheel sizes, materials, and mounting options available, users can select casters that best meet their specific needs.

3. Choosing the Right Medium Duty Casters for Your Needs

Selecting the appropriate casters is crucial for achieving maximum performance. Consider the following factors:

- **Load Capacity**: Ensure the casters can handle the weight of the items you intend to move.

- **Wheel Material**: Choose between rubber, polyurethane, or plastic based on the surface type and environmental conditions.

- **Swivel vs. Rigid**: Determine if you need swivel casters for maneuverability or rigid casters for straight-line movement.

- **Height**: The height of the caster affects the overall height of your equipment, impacting usability.

4. Essential Tools and Materials for Installation

Before beginning the installation of medium duty casters, gather the following tools and materials:

- **Drill with Drill Bits**: Essential for creating mounting holes.

- **Wrench or Socket Set**: For tightening nuts and bolts.

- **Screwdriver**: Depending on the type of screws used for the casters.

- **Measuring Tape**: For accurate placement.

- **Level**: To ensure your equipment is even after installation.

- **Casters**: Ensure they are of medium duty and appropriate for your application.

5. Step-by-Step Guide to Installing Medium Duty Casters

Installing medium duty casters requires careful planning and execution. Follow these steps for a successful installation:

5.1 Preparing the Surface

Begin by cleaning the surface where the casters will be installed. Remove any debris, dust, or old paint to ensure a secure attachment. If you're working with furniture or a cart, ensure it is upright and stable.

5.2 Marking the Installation Points

Using a measuring tape, determine where each caster will be attached. Mark the points clearly with a pencil to maintain accuracy. It's essential to ensure that the casters are evenly spaced and aligned with the structure for stability.

5.3 Attaching the Casters

Drill holes at the marked points using an appropriate drill bit. Once the holes are drilled, align the casters with the holes and use screws or bolts to secure them firmly. Ensure that all screws are tightened properly, but avoid over-tightening, which could damage the caster or the surface.

5.4 Testing the Installation

After installation, test the casters by gently pushing the equipment. Check for any wobbling or uneven movement. If necessary, make adjustments to ensure a smooth operation.

6. Maintenance Tips for Long-Lasting Performance

Maintaining your medium duty casters is essential for long-term performance. Consider these tips:

- **Regular Inspections**: Check for any wear or damage to the wheels and brackets.

- **Cleaning**: Keep the wheels free from debris and dirt. A simple wipe-down with a damp cloth usually suffices.

- **Lubrication**: Periodically lubricate swivel mechanisms and bearings to ensure smooth movement.

- **Weight Management**: Avoid exceeding the load capacity to prolong caster life.

7. Common Mistakes to Avoid When Installing Casters

To achieve optimal performance, it is essential to avoid common pitfalls:

- **Ignoring Load Capacities**: Always check that the casters can support the intended load.

- **Improper Alignment**: Misalignment can lead to instability and increased wear.

- **Neglecting Surface Compatibility**: Ensure that the wheel material is suitable for the floor surface to prevent damage or excessive wear.

- **Skipping Maintenance**: Regular upkeep is crucial for maintaining functionality.

8. Frequently Asked Questions (FAQs)

**Q1: How do I know which casters are right for my application?**

A1: Evaluate the weight requirements, surface type, and intended maneuverability before selecting casters.

**Q2: Can I install casters on any surface?**

A2: Yes, but surface compatibility is crucial. Ensure the wheel material is suitable for your floor type.

**Q3: Do I need special tools for installing casters?**

A3: Basic tools such as a drill, wrench, and measuring tape are typically sufficient for installation.

**Q4: How often should I lubricate my casters?**

A4: It's recommended to lubricate casters every few months or more frequently depending on usage conditions.

**Q5: What should I do if a caster breaks?**

A5: Replace the damaged caster promptly to maintain functionality and safety.

9. Conclusion

In conclusion, properly installing medium duty casters is essential for achieving maximum performance and ensuring longevity. By understanding the nuances of caster selection, installation techniques, and maintenance practices, you can enhance the mobility and efficiency of your equipment. With this comprehensive guide, we hope you feel equipped to tackle your caster installation with confidence and skill. Embrace the power of mobility and make your tasks easier and safer today!

Key words:

RELATED NEWS

How to Properly Install Medium Duty Casters for Maximum Performance

2025-09-27

How to Properly Install Medium Duty Casters for Maximum Performance

Table of Contents

1. Understanding Medium Duty Casters

2. Benefits of Using Medium Duty Casters

3. Choosing the Right Medium Duty Casters for Your Needs

4. Essential Tools and Materials for Installation

5. Step-by-Step Guide to Installing Medium Duty Casters

5.1 Preparing the Surface

5.2 Marking the Installation Po

Understanding Grey Casters: A Comprehensive Guide to Their Benefits and Applications

2025-09-20

When it comes to enhancing mobility in various applications, grey casters have gained significant popularity due to their unique characteristics and benefits. Grey casters are designed with a rubber material that is typically softer and quieter compared to traditional hard plastic or metal wheels. This makes them ideal for environments where noise reduction and floor protection are essential.

One

Safety First: The Importance of Using Diamond Casters in Workspaces

2025-09-13

Safety First: The Importance of Using Diamond Casters in Workspaces

Table of Contents

Introduction to Diamond Casters

What Are Diamond Casters?

Benefits of Using Diamond Casters in Workspaces

Enhanced Safety Features

Improved Mobility and Flexibility

Durability and Reliability

Applications of Diamond Casters in Various Industri