BLOG

Unleashing Efficiency: A Comprehensive Guide to Industrial Casters for Your Business

2025-10-04

Industrial casters are pivotal components in the realm of heavy-duty material handling and logistics. Their primary function is to facilitate the movement of equipment, tools, and furniture, contributing significantly to operational efficiency across various industries, including manufacturing, warehousing, and distribution. Understanding the nuances of industrial casters can lead to improved prod

Industrial casters are pivotal components in the realm of heavy-duty material handling and logistics. Their primary function is to facilitate the movement of equipment, tools, and furniture, contributing significantly to operational efficiency across various industries, including manufacturing, warehousing, and distribution. Understanding the nuances of industrial casters can lead to improved productivity and reduced operational costs.

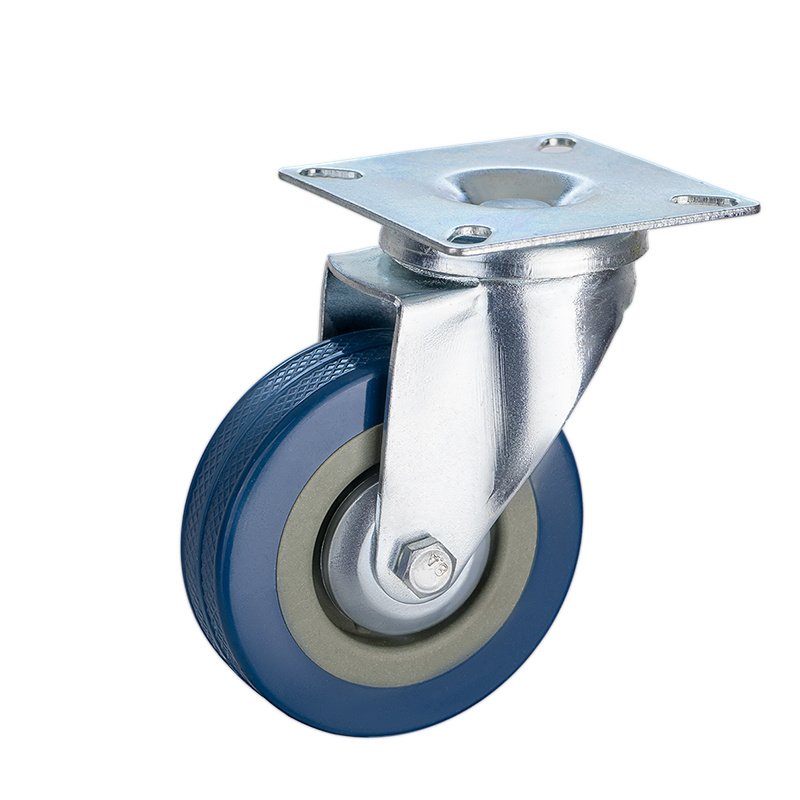

When selecting industrial casters, the first consideration should be the type of caster appropriate for your specific application. There are primarily two categories of industrial casters: rigid and swivel. Rigid casters are designed to move in a straight line, providing stability and support, while swivel casters offer greater maneuverability, allowing for easier navigation in confined spaces. Depending on the layout of your workspace, a combination of both types may yield the best results.

Material composition is another critical factor to evaluate. Industrial casters can be constructed from various materials, including rubber, polyurethane, and metal. Rubber casters are excellent for noise reduction and floor protection, whereas polyurethane casters are known for their durability and ability to withstand heavy loads. Metal casters, on the other hand, are ideal for extreme environments where high heat or chemicals are present. Choosing the appropriate material not only affects the caster’s performance but also impacts its longevity and maintenance requirements.

Load capacity is a crucial parameter to consider as well. Each caster has a rated load capacity, which denotes the maximum weight it can safely support. It is essential to calculate the total weight of the items that will be mounted on the casters and select those that exceed this weight to ensure safety and reliability.

Furthermore, the wheel diameter plays a significant role in the caster's ability to navigate obstacles. Larger wheels can roll over uneven surfaces more easily, making them ideal for warehouse floors or outdoor applications. Conversely, smaller wheels are best suited for smooth surfaces where high maneuverability is essential.

Lastly, pay attention to the caster's braking mechanisms. Casters equipped with brakes can enhance safety by preventing unwanted movement when the equipment is stationary. There are several types of brakes, including total locks and directional locks, each catering to different operational needs.

In summary, understanding the various factors associated with industrial casters—from type and material to load capacity and braking options—can significantly enhance the efficiency of your operations. By carefully selecting the right casters, businesses can improve workflow, increase safety, and ultimately achieve higher productivity levels. This knowledge is vital for anyone involved in the procurement or management of industrial equipment and materials.

When selecting industrial casters, the first consideration should be the type of caster appropriate for your specific application. There are primarily two categories of industrial casters: rigid and swivel. Rigid casters are designed to move in a straight line, providing stability and support, while swivel casters offer greater maneuverability, allowing for easier navigation in confined spaces. Depending on the layout of your workspace, a combination of both types may yield the best results.

Material composition is another critical factor to evaluate. Industrial casters can be constructed from various materials, including rubber, polyurethane, and metal. Rubber casters are excellent for noise reduction and floor protection, whereas polyurethane casters are known for their durability and ability to withstand heavy loads. Metal casters, on the other hand, are ideal for extreme environments where high heat or chemicals are present. Choosing the appropriate material not only affects the caster’s performance but also impacts its longevity and maintenance requirements.

Load capacity is a crucial parameter to consider as well. Each caster has a rated load capacity, which denotes the maximum weight it can safely support. It is essential to calculate the total weight of the items that will be mounted on the casters and select those that exceed this weight to ensure safety and reliability.

Furthermore, the wheel diameter plays a significant role in the caster's ability to navigate obstacles. Larger wheels can roll over uneven surfaces more easily, making them ideal for warehouse floors or outdoor applications. Conversely, smaller wheels are best suited for smooth surfaces where high maneuverability is essential.

Lastly, pay attention to the caster's braking mechanisms. Casters equipped with brakes can enhance safety by preventing unwanted movement when the equipment is stationary. There are several types of brakes, including total locks and directional locks, each catering to different operational needs.

In summary, understanding the various factors associated with industrial casters—from type and material to load capacity and braking options—can significantly enhance the efficiency of your operations. By carefully selecting the right casters, businesses can improve workflow, increase safety, and ultimately achieve higher productivity levels. This knowledge is vital for anyone involved in the procurement or management of industrial equipment and materials.

Key words:

RELATED NEWS

Unleashing Efficiency: A Comprehensive Guide to Industrial Casters for Your Business

2025-10-04

Industrial casters are pivotal components in the realm of heavy-duty material handling and logistics. Their primary function is to facilitate the movement of equipment, tools, and furniture, contributing significantly to operational efficiency across various industries, including manufacturing, warehousing, and distribution. Understanding the nuances of industrial casters can lead to improved prod

How to Properly Install Medium Duty Casters for Maximum Performance

2025-09-27

How to Properly Install Medium Duty Casters for Maximum Performance

Table of Contents

1. Understanding Medium Duty Casters

2. Benefits of Using Medium Duty Casters

3. Choosing the Right Medium Duty Casters for Your Needs

4. Essential Tools and Materials for Installation

5. Step-by-Step Guide to Installing Medium Duty Casters

5.1 Preparing the Surface

5.2 Marking the Installation Po

Understanding Grey Casters: A Comprehensive Guide to Their Benefits and Applications

2025-09-20

When it comes to enhancing mobility in various applications, grey casters have gained significant popularity due to their unique characteristics and benefits. Grey casters are designed with a rubber material that is typically softer and quieter compared to traditional hard plastic or metal wheels. This makes them ideal for environments where noise reduction and floor protection are essential.

One